Precision Engineering

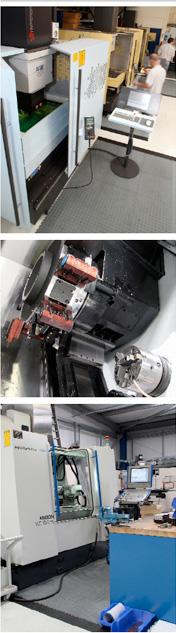

GB Precision specialises in offering the highest quality precision engineering;

including Wire EDM, Diesink EDM and full CNC machining and grinding services.

Our policy of continuous investment ensures that we can offer customers the

benefits of the latest machine tool technology.

Through this investment, including our off-line palletisation system, we have reduced

setting and cutting times, improved productivity, achieved better surface finish and

increased reliability, providing our customers with premium quality work – quality-checked on site – in the shortest possible time.

CNC MACHINING

We have comprehensive CNC Milling and Turning capacity, for the production of

complex electrodes and tooling as well as for the short-run production of

components

Milling

* NEW capacity and capability installed in 2014

- Röders 5 Axis High Speed Machining Centres

- CNC Milling capacity up to 500mm x 400mm x 250mm high

- 5axis Mikron milling machine with full multi axis CADCAM programming capabilities

- High speed Bostomatic machining centre for production of complex form electrodes

Turning

- CNC Turning capacity up to 200mm dia.x 400mm length

- 4 axis Mori Seiki lathe with Subspindle and Live Tooling for 1-hit machining

- Super-precision Hardinge lathe for fine finishes and form accuracy

WIRE AND SPARK EROSION

We have installed the latest machines, providing higher removal rates combined with

high surface finish and accuracy, all with CNC control

Wire Erosion

* NEW capacity and capability installed in 2012

- Large working capacity 350mm x 250mm x 250mm high

- Significant experience eroding a wide variety of materials

- Small wire capability down to 0.07mm diameter

- Twin Wire Circuit Machine for flexible production

- 30° maximum angle capability

Die Sink Erosion

- Large working capacity 350mm x 250mm x 300mm high

- Latest palletisation tooling giving zero setting times

- Latest high performance generators for fast erosion and fine finishes

GRINDING

CNC Cylindrical Grinding

* NEW capacity and capability installed in 2014

- Utilising state of the art Studer machines for their capability to produce exacting tolerance and form integrety

- Capacity 350mm Dia x 600mm long

- Out of Round capability for Cam or Punch forms as well as eccentric diameters

- High accuracy thread grinding capability

- Capability to produce complex forms, tapers, spherical shapes or any

combination

- Extensive experience and tooling to produce highly varied components

- Dedicated Grinding Section CMM for complex inspection during part processing

Surface Grinding

- Capacity 400x150x300

- Optidress & Diaform systems for producing complex forms and features.

METROLOGY

CNC CMM

* NEW capacity and capability installed in 2011 all contained within a newly built metrology lab

- Mitutoyo CMMs with Large working area 1000x600x500 (2nd Machine installed in 2011)

- Full CNC control including probe change rack and probe orientation for

measuring complex parts with wide variety of features in 1 setup

- Scanning capability

- Contour Tracer installed in 2011 for detailed analysis of both internal and external forms and surface features

- Roundness Tester installed in 2011 for high accuracy geometric measurements of featueres such as roundness, concentricity, perpendicularity and many more

- Surface Roughness measurement equipment capable of measuring surface finish on both flat

and curved surfaces

- Attachments to allow measurement in small bore diameters

- Microscope and projection equipment for detailed inspection of profile and

visually defined features

- As well as an extensive range of the usual toolroom measuring instruments and

fixtures.

|